With housing shortages on the rise and more people looking for sustainable building methods, it’s no wonder prefab homes (short for prefabricated) are growing in popularity.

Prefab homes are nothing new. But with modern technologies and building methods, more builders are offering prefab homes to their clients.

This guide gives you an overview of prefab homes so you can figure out if adding prefab homes to your services makes sense for you and your clients.

Key Takeaways

- Prefab homes offer faster build times, reduced waste, and lower costs compared to traditional housing construction.

- Design flexibility and modern manufacturing methods make prefab homes a viable option for a wide range of homeowners and housing professionals.

- Total project costs vary depending on home type, site preparation, foundation, and utility connections.

- Cedreo helps housing pros streamline prefab home design with 2D/3D tools, customizable layouts, and presentation-ready project documents.

Why trust us? Here at Cedreo, we’ve got 20+ years of experience working with housing pros in the home design space. We know what it takes for home builders, contractors, and designers to create prefab home plans that land them more jobs!

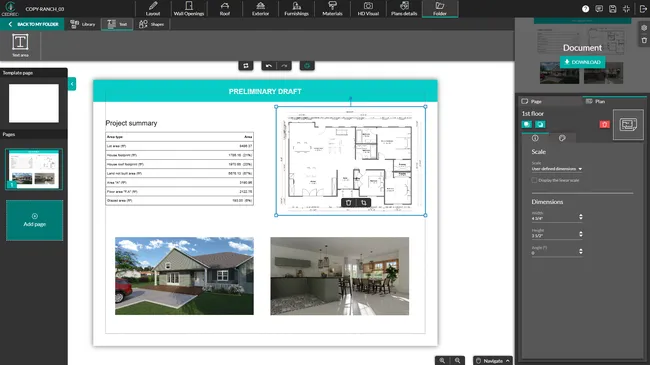

See How You Can Create Complete Projects with Cedreo

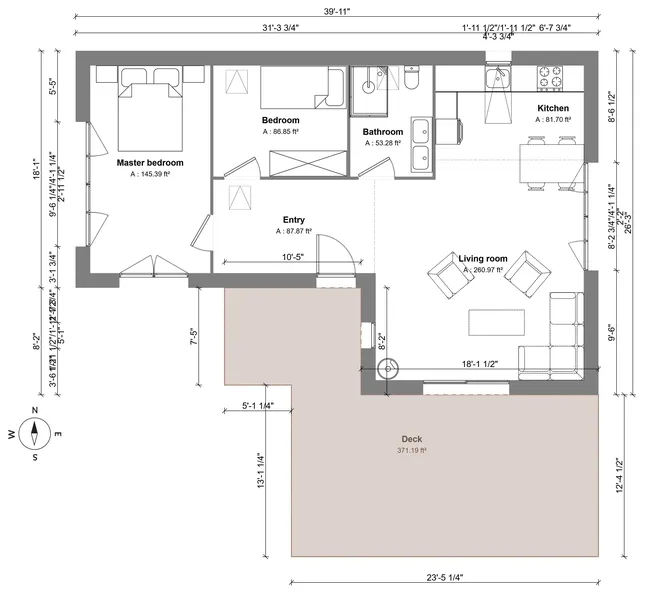

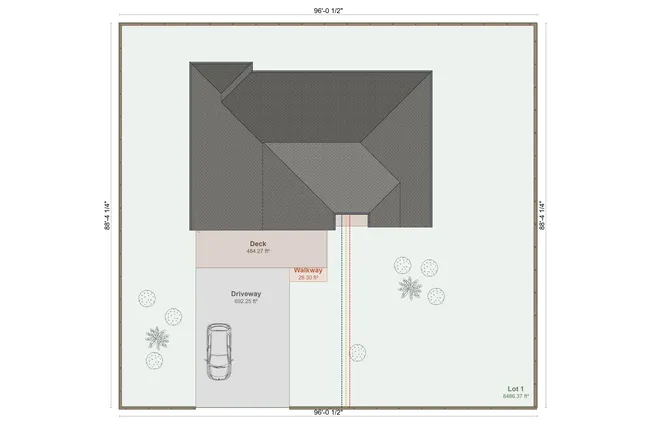

Plans – Get site plans, 2D floor plans, electrical plans, cross sections and elevation views — with all the technical details you need for a comprehensive project overview.

3D Visualizations – Use interior and exterior 3D renderings as well as 3D floor plans to help clients understand the finished project.

Documentation – Manage all your visual documents in one place, so it’s easier to present and sell your projects.

No credit card required, no commitment

What Is a Prefab Home?

What do you think of when you hear the term “prefab home”? You might first think of a mobile home or “trailer” as they’re sometimes called. And it is true that technically, a mobile home is a type of prefabricated home. But modern prefab homes are so much more!

So what exactly is a prefab home?

A prefab home is a home that is, entirely or in part, manufactured off-site and then transported to a property and assembled. Sometimes the entire home may be built in one piece in a factory. And other times, parts of the home (like wall panels or bathroom pods) are built in a factory and then assembled on-site.

Types of Prefab Homes

Prefab homes come in several formats, each with its construction process, building code requirements, and level of on-site labor. Here are the four main types.

Manufactured Homes

Also known as mobile homes, trailers, or single-wides, these are fully built in a factory and transported in one piece to the home site.

- Built to HUD code (not local IRC codes)

- Delivered complete, minimal on-site work required

- Usually set on non-permanent foundations

- Subject to transport and delivery restrictions based on size and location

Modular Homes

Modular homes are built in large sections off-site, then assembled on a permanent foundation.

- Meet the same local building codes (IRC) as site-built homes

- Highly customizable in terms of layout and finishes

- Can be installed on permanent foundations

- Often indistinguishable from traditional homes

Kit Homes

Kit homes arrive as pre-cut components or partially assembled modules for on-site construction.

- Lower cost (compared to site-built) while still offering plenty of customization options depending on the manufacturer

- Delivered as parts, not finished sections

Panelized Homes

Wall and roof panels are pre-built in a factory, shipped flat, and assembled on-site.

- Reduces weather delays and onsite waste (compared to traditional stick-built homes)

- Ideal for hybrid builds where homeowners need more customization

How Much Do Prefab Homes Cost?

While base prices for prefab homes are often very attractive, the total project cost can vary widely depending on land conditions, home type, site preparation, foundation, permits, and utilities.

Here’s a breakdown to help you estimate:

Base Unit Costs (Factory Price)

- Modular homes: $80–$160/sq ft | $160,000–$365,000 for most family homes

- Manufactured homes: $81,000–$165,000+

- Kit homes: $30–$150/sq ft (kit only)

- Panelized homes: Kits start around $100,000

Additional Prefab House Costs to Consider

- Site preparation: $20,000–$50,000+. Land clearing, excavation, grading, soil testing

- Foundation: $6,000–$30,000+. Slab, crawl space, or full basement

- Utilities hookups: $6,500–$30,000+. Sewer, septic, water, electricity, gas

- Installation & assembly: $10,000–$50,000+. Crane lifts, set crews, weather sealing

- Permits & fees: $1,500–$7,500. Building permits, impact fees, inspections

- Finishes & customization: $30–$60/sq ft. Interior fixtures, flooring, cabinetry, appliances

Pros and Cons of Prefab Homes

Prefab homes offer a range of benefits. They also come with a few challenges that you need to factor into project planning and client expectations.

Prefab Home Pros

- Speed: Since most of the construction happens in a controlled off-site factory, prefab homes are far less susceptible to weather delays. Once delivered, you can usually assemble them in days, not months.

- Affordability: Building in a factory allows for streamlined workflows, reduced waste, and less labor. For builders who can manage site prep and assembly, prefab homes offer significant savings over traditional construction.

- Customization options: Today’s prefab manufacturers offer a surprising level of personalization. Clients can tweak floor plans, materials, and interior fixtures while still benefiting from a mass-produced base.

- Energy efficiency & durability: Despite outdated assumptions, today’s modular and manufactured homes are designed to meet strict building codes and can be just as durable and energy-efficient as site-built homes.

Prefab Home Cons

- Financing hurdles: Many financial institutions don’t offer traditional mortgages for some types of manufactured or modular homes. This can depend on various factors, such as whether the homeowner is purchasing land and putting the home on a permanent foundation. Homeowners need to investigate financing options such as separate land and construction loans, personal loans, or specialty financing.

- Permit & zoning complexity: Obtaining permits can be tricky if local officials are unfamiliar with prefab structures. In some areas, zoning laws may restrict or prohibit certain types of manufactured homes, especially those not placed on a permanent foundation.

- Delivery limits & site constraints: Long-distance shipping adds cost and increases the risk of damage in transit. Plus, some prefab builders have geographic delivery limits or won’t deliver to remote or difficult terrain.

- Depreciation risks: Some manufactured homes, especially lower-cost models on non-permanent foundations, don’t hold their value well over time.

- Foundation still required: Even with off-site construction, you’ll still need to budget for excavation, a foundation, and utility connections, which can raise costs to levels comparable with site-built homes.

Prefab Home Design Tips & Ideas

Here are five expert design strategies tailored specifically to prefab homes.

Space Planning

Why it’s important for prefab homes:

Prefab homes require strategic space planning since modular units have fixed dimensions. And because prefab houses are built in complete sections, adjusting space after installation isn’t easy.

Tips for housing pros:

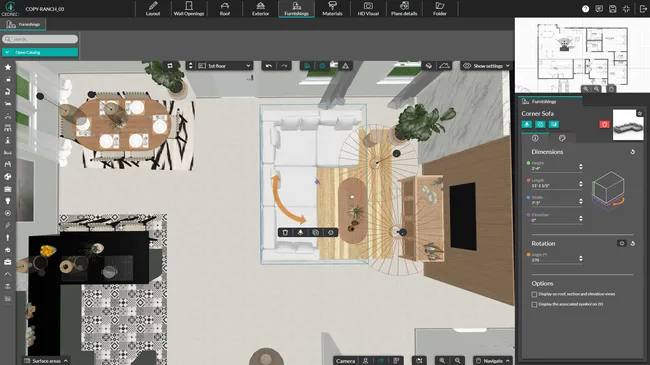

- Use furniture placement to visually define areas without adding interior walls.

- Go with open concept kitchen/dining/living zones in single family homes to maximize layout flexibility.

- Position bathrooms and kitchens back-to-back to simplify plumbing and electricity.

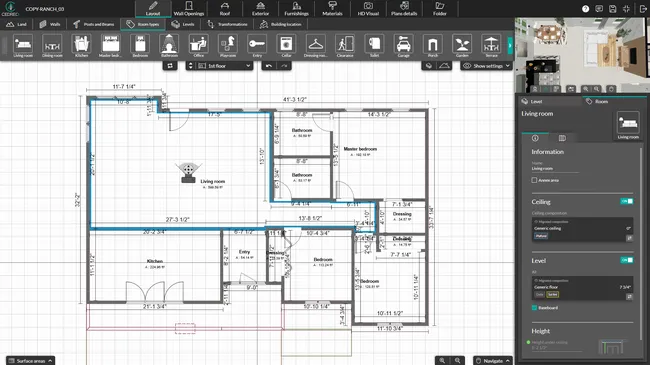

- Use Cedreo’s floor plan creator to quickly test different layouts within prefabricated room modules.

Visualization Mockups with Cedreo

Why it’s important for prefab homes:

Since many prefab homes are finalized before shipping, accurate 3D visualization is a must. Cedreo makes it easy to preview complete sections, test layout options, and present polished designs before construction begins.

Tips for housing pros:

- Render full-home mockups showing prefab sections joined together.

- Use Cedreo to present multiple finish packages for quick client decisions.

- Generate cross-sections and elevations.

- Include electrical plans and furniture layouts in presentation docs.

Prefab Home Interior Style Trends

Why it’s important for prefab homes:

Styles like minimalist, Scandinavian, and industrial tend to work well with prefab construction. They emphasize clean lines, raw materials, and simplicity. These styles can even reduce finishing labor and work well with sustainable housing materials.

Plus, they provide a flexible foundation that homeowners can easily personalize with their own décor, furniture, and design tweaks, without being locked into a rigid aesthetic.

Tips for housing pros:

- Use exposed beams or plywood panels for a cost-effective industrial touch.

- Light wood finishes, soft neutrals, and simple forms capture the warmth and functionality of Scandinavian-inspired design.

- For minimalist layouts, limit visual clutter by designing built-in storage and choosing a restrained material palette.

- Use materials from Cedreo’s design library to create variations of your prefab designs to match each style trend.

Design for Transport and Assembly

Why it’s important for prefab homes:

Every prefab design must account for how modules are delivered and joined. Oversized components increase costs and risk delays.

Tips for housing pros:

- Check federal and local state laws.

- In many places, modules or homes less than 8.5 feet wide don’t require pilot cars and route restrictions.

- Some modular sections as wide as 15-16 feet can be transported, but require special permits.

- Reinforce roof and floor systems to withstand lifting stress.

- Pre-plan crane access points and lifting straps during layout.

- Label utility access zones for quick on-site hookup of electricity and plumbing.

Design for Energy Efficiency

Why it’s important for prefab homes:

Older modular and manufactured homes earned a reputation for poor energy efficiency. This was due to thin insulation, leaky seams, or being placed on pier foundations that left plumbing exposed to freezing temperatures. Designing with energy efficiency in mind helps reduce utility costs and protect the home from weather extremes.

Tips for housing pros:

- Use high R-value insulation in walls and floors

- Position windows to maximize passive solar gain in winter and shade in summer

- Recommend sealed crawl spaces or install high-quality skirting

- Place prefab homes on a permanent foundation when possible

Balance Customization Options with Standardization

Why it’s important for prefab homes:

To stay affordable, prefab homes should be partially standardized, but still offer enough flexibility to meet client expectations. By designing adaptable modules, you can speed up construction while offering just-right personalization.

Tips for housing pros:

- Offer preset layouts with optional upgrades (e.g., extended decks or alternate kitchen finishes).

- Design “wet zones” (bath, kitchen) to remain static with options to adjust other parts of the layout.

- Use Cedreo to create reusable project templates that you can customize per client.

- Suggest finish packages tailored to the location (urban, coastal, mountain).

- Include pre-approved structural options that don’t require reengineering for every project.

How to Design a Prefabricated Home

With the right tools, you can quickly go from concept to client-ready presentation without any previous CAD or 3D modeling experience.

Here’s a simple step-by-step process for creating a professional prefab home design using Cedreo.

Step 1: Start with Site Preparation and Construction Constraints

Before you begin your design, think about the site and type of prefab home you’re building. Is it modular, panelized, or a kit home? What are the transport limits? What’s the terrain like? Consider things like:

- Lot size and zoning rules

- Permanent foundation requirements

- Utility access and orientation

- Lifestyle goals of the client

These factors shape how your design takes form.

Step 2: Sketch the Floor Plan in 2D

Use Cedreo’s floor plan tools to draft the layout. Draw walls, and drag and drop windows and doors into place. Push and pull walls to adjust dimensions to optimize for transportable sections.

Step 3: Visualize in 3D as You Design

Use Cedreo’s 3D view to instantly see how your floor plan looks in real life. This helps you refine architectural details like roof shapes, exterior materials, and lighting well before construction.

Step 4: Customize Finishes and Layout Variants

Choose from thousands of finishes, furniture pieces, and materials to create a prefab home that feels anything but “standard.” You can even duplicate the design to create multiple layouts for different budgets or clients. This is perfect for creating standard modular home kits you can customize for specific clients without having to start from scratch.

Step 5: Show the Home on the Actual Site

Once the home design is finalized, use Cedreo’s tools to model the terrain and draw a detailed site plan. This step helps clients visualize how their prefab home will look on their actual land.

Step 6: Export Presentation-Ready Documents

With just a few clicks, Cedreo generates all the documentation you need for client approvals, including:

- 3D renderings

- Floor plans

- Site plans

- Cross sections & elevations

- Electrical plans

PRO TIP: Sharing polished project presentations early helps align expectations and reduce delays with client approvals or change requests later in the construction process.

3 Best Types of Software for Designing Prefabricated Homes

When you’re designing prefabricated homes, the right software can save time, reduce rework, and help you win client approvals faster. Here are your top options.

Cedreo (Best for Prefab Housing Pros)

Cedreo is perfect for home builders, remodelers, and designers who want to create professional prefab home layouts without needing CAD experience. Its drag-and-drop tools let you build detailed 2D floor plans and visualize them in 3D in real time.

Cedreo’s strength lies in speed and clarity. You can design entire homes in hours, not days, and generate client-ready visuals and technical docs, like cross sections, elevations and electrical plans, all from one cloud-based platform.

Why Cedreo is perfect for prefab housing pros:

- Draw 2D floor plans and instantly preview in 3D

- Add furniture, materials, and finishing touches

- Export 3D renderings, elevations, and electrical plans

- Share presentations with clients and other stakeholders

Try Cedreo FREE to design your next prefab project faster.

SketchUp

SketchUp is a well-known 3D modeling tool popular for conceptual designs. It’s flexible and supported by a massive online library, but can be time-consuming for detailed prefab layouts.

- Huge library of user-generated 3D models

- Use 3D tools to create custom shapes and designs

- Good for styling exteriors and interiors with paid add-ons

- Limited floor plan and construction document features (unless you purchase add-ons and extensions)

Revit

Revit is a popular BIM (Building Information Modeling) platform used in large-scale architecture. It excels at code compliance, technical detail, and collaboration. However, its complexity and cost make it overkill for most residential prefab housing projects.

- Comprehensive BIM tool for building codes and permitting

- Great for managing utilities and materials

- Supports floor systems and structural planning

- Expensive and has a steep learning curve

Prefab Home Design With Cedreo!

Designing prefab homes doesn’t have to be complex, especially when you have the right tools. Cedreo simplifies every step of the process so you can focus on what matters…your clients.

Here’s how Cedreo helps you succeed with prefab projects:

- Design modular-friendly floor plans with 2D and 3D views in real time

- Customize materials, finishes, and furnishings to match client budgets and lifestyle needs

- Generate presentation-ready documents like cross sections, elevations, and electrical plans

Prefab Houses FAQs

A prefabricated home is constructed off-site in sections and then assembled on the homeowner’s property. These homes are typically modular, manufactured, kit, or panelized and are known for their build efficiency, speed, and cost savings.

Prefab homes are typically more affordable than traditional stick-built homes. While the base price can be lower, total cost can vary depending on factors like site prep, foundation, and utilities.

Modular homes are a type of prefab home. The term “prefab” includes several construction styles. Modular homes are built in large sections and meet local building codes. They can be permanently installed on a foundation at the home site and may qualify for standard mortgage options.

Yes, most prefab homes require some sort of foundation, whether it’s a slab, crawl space, or basement. Some modular and manufactured homes don’t require a permanent foundation. However, a prefab home constructed on a permanent foundation still offers attractive affordability while potentially qualifying for a standard mortgage loan.

Well-built prefab homes can last 30–60+ years, depending on materials, quality of installation, and maintenance.

Yes, many prefab homes, including modular and manufactured units, can be installed on a slab foundation. This is a cost-effective option that increases installation speed and energy efficiency.